Short Distance Series Product Model

Long Distance Series Product Model

Kilometer-level

Long Distance Series Product Model

The intelligent rail-guided transport system connects transmission stations in different areas via specific tracks. Specialized transport vehicles travel along these fixed tracks, enabling three-dimensional, point-to-point transportation between stations. To improve the operational efficiency of the pallet transport robots, multiple robots can run simultaneously. To prevent collisions between these robots, Benewake has introduced a LiDAR obstacle avoidance solution, ensuring safe operation of the robots and reducing property damage.

Compared to traditional photoelectric switch sensors, the Benewake TF-NOVA line patter laser beam LiDAR offers a significant upgrade in intelligence, accurately and capturing the distance to objects ahead. TF-NOVA provides 14° and 1° horizontal coverage, effectively monitoring the core area of Pallet Transport Robot (RGV). Its narrow vertical scanning range perfectly fits the slim design requirements of RGV, reducing false triggers caused by larger vertical spot sizes.

In contrast to Benewake's single-point LiDARs (like the TFmini-Plus), TF-NOVA significantly reduces false alarms in long-distance detection. Single-point LiDARs often misidentify RGV shelves or crossbeams as obstacles, but the TF-NOVA effectively addresses this issue, enhancing the efficiency and safety of RGV operations.

Core Advantages

Ideal Angle for the application: With a horizontal coverage of 14°, TF-NOVA avoids false alarms from too narrow an angle at long distances and blind spots from too wide an angle at short distances. The vertical 1° field of view minimizes false triggers caused by large spot sizes, ensuring accurate and reliable detection.

High Sensitivity: With a detection frequency of 500 Hz, TF-NOVA quickly identifies fast-moving small targets with low reflectivity, making it suitable for high-speed operation of up to 5m/s and effectively capturing sudden obstacles.

Simplified Integration: It supports I/O output, UART, and I2C interfaces, allowing for rapid integration into existing systems.

Strong Environmental Adaptability: The IP65-rated infrared filter window protects against dust and water while effectively reducing interference from cross beams and sunlight.

Key Recommended Products:

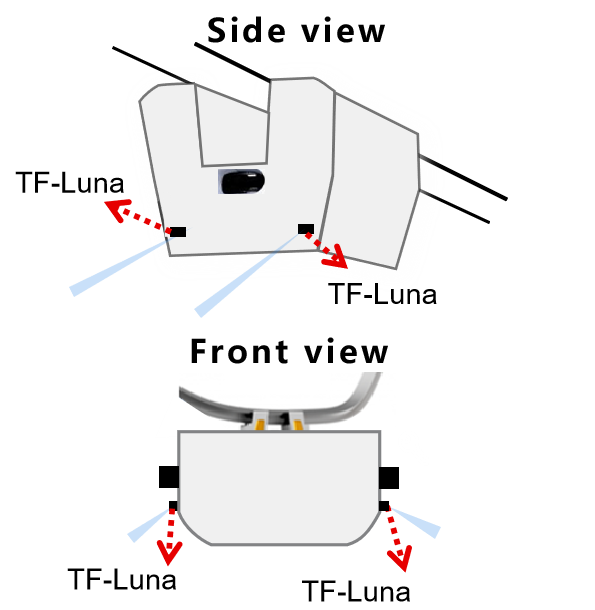

Following delivery instructions from the control center, intelligent vehicles travel along overhead rails to material delivery point A and transport the materials to station B via horizontal or vertical tracks. This achieves fast, contactless intelligent material transportation. To prevent collisions between multiple overhead rail robots during operation, two TF-Luna low-cost LiDAR distance measurement modules are installed at both the front and rear of the robots (as shown in the diagram) to detect distances. When an obstacle is detected during operation, the inspection robot triggers an alarm and decelerates or stops immediately, ensuring the safe operation of the overhead rail inspection robots.

Core Advantages

1. High-Speed Operation Compatibility: Default detection frequency of 100Hz, configurable up to 1000Hz, ensuring rapid and timely response;

2. Real-Time Output: Outputs real-time distance values and signal strength values, with simple data parsing and enhanced reliability through signal strength values.

3. Rich Interfaces: Supports various data interfaces including UART, I²C, 4-20mA, RS-232, and RS-485.

4. Strong Interference Resistance: Resistant to environmental light interference up to 100Klux; highly adaptable with no requirements for reflective surfaces, eliminating the need for additional high-reflectivity plates.

5. Narrow FoV: Low false alarm rate, precise distance measurement, compact size, and easy integration within the vehicle body.

Key Recommended Products: