VLS Series

Long Distance Series Product Model

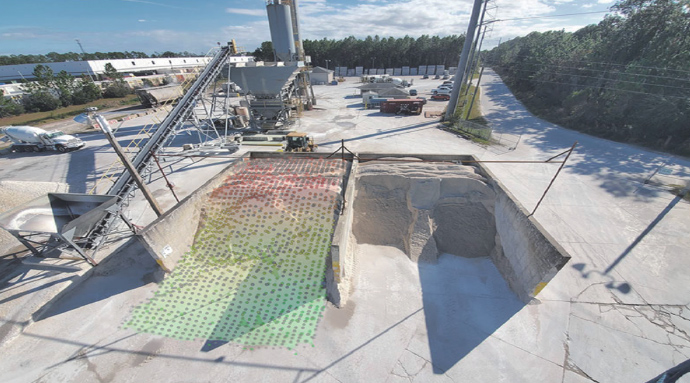

In agricultural settings, there are a large number of facilities such as silos and granaries. The existing material level detection methods are less automated, and more than 80% of them still choose to manually climbing to the top of the tank for observation, which is inefficient, even has high security risk. By installing the Benewake LiDAR in the tank, it can detect the height of the material level in real time and feedback the data to the background. Effective data can increase the efficiency of production and transportation.

Applications

|  |  |

Ore raw material | Industrial raw materials | Fodder, crops |

In automated agricultural machinery, there are many hoppers. LiDAR can be used to monitor the fullness of the hoppers in real-time, reducing the need for manual labor and enhancing operational safety.

As the number of basic infrastructure construction projects in various cities gradually increases, dump trucks are important transportation vehicles in urban engineering construction. They often encounter problems such as overloading and speeding, becoming one of the major safety hazards on urban roads. Many cities in China have not yet achieved unified intelligent management, leading to difficulties in supervision. In order to solve the problem of vehicle overloading and management from the source and reduce the probability of traffic accidents caused by overloading.

By installing Benewake single-point LiDAR at the front of the truck compartment, real-time detection and identification of the compartment status are achieved, including empty and full load states, tarpaulin/iron plate sealing states, compartment lifting states, and other behaviors. Providing real-time data support for unified management is conducive to reducing urban traffic hazards.

|  |  |

1. Performance: The device measures at a high frequency, providing real-time distance feedback. It features a small beam divergence angle with a maximum field of view of only 3°, eliminating multiple echo interference issues and maintaining a low false alarm rate. Additionally, it is compact and lightweight, making it easy to integrate and install.

2. Power Consumption: In low power mode, the power consumption is less than 100mW, and in ultra-low power standby mode, it is less than 10mW. It is battery-powered with a low battery replacement frequency, reducing manpower requirements.

3. Price: This lidar product is priced in the hundred-yuan range, while similar range radar level meters typically cost at least a thousand yuan, making level detection more accessible to a broader range of customers.

4. Dust Removal: The TF02-Pro-W model includes a built-in dust removal component, and some models offer optional dust removal accessories, eliminating the need for manual cleaning. The dust removal accessory has a lifespan of at least 80,000 operations at room temperature, solving the issue of material buildup in level detection.

5. Environmental Adaptability: The device has strong resistance to ambient light and is unaffected by day or night and temperature variations. It can accurately monitor distance information inside compartments in various environments.

6. Industrial Version: The Benewake industrial version lidar supports a wide voltage input range of 7-30V and can be directly powered by vehicle batteries, eliminating the need for additional battery modules.