VLS Series

Long Distance Series Product Model

Leveraging its outstanding technology and extensive project experience, Benewake provides comprehensive fall prevention and obstacle avoidance solutions for robots. Whether it's for robot fall prevention, obstacle avoidance, AMR/AGV/RGV obstacle avoidance, or forklift fork obstacle avoidance, Benewake ensures that robots can operate safely and efficiently in complex environments across any industrial or service robot field.

Robust obstacle avoidance is crucial for safe robot operation, requiring the ability to instantly and accurately identify the surrounding environment to effectively prevent collisions and mitigate safety hazards.

Benewake TF-NOVA line patter laser beam LiDAR can be mounted at the front of a robot to emit a line of laser. With a horizontal field of view (FOV) of 14°, a single TF-NOVA can create a detection area of about 48 cm within 2 meters in the robot's movement direction—an area that would typically require multiple single-point LiDAR or a costly single-line LiDAR. Any obstacles within this range are accurately detected, allowing for rapid control of the robot's speed or emergency stop through I/O interfaces.

TF-NOVA is suitable for various commercial service robots in applications such as food delivery, logistics, and public cleaning.

Core Advantages

Ideal Angle for the application: 14°*1° FoV effectively covers the obstacle avoidance width for mobile robots. At 1 meter, it detects obstacles across a width sillimar as a single person, meeting the demands of various environments.

Sensitive Detection of Small Low-Reflectivity Targets: TF-NOVA can accurately identify low-reflectivity small targets, ensuring that as small as a 5 cm² black target (10% reflectivety) is detected anywhere within 2 meters. This ensures timely detection of potential obstacles in complex environments, enhancing robot safety and operational efficiency.

Flexible Multi-Interface Support: TF-NOVA offers multiple interfaces (UART, IIC, I/O), making it ideal for both standalone and networked applications. This versatility ensures easy deployment across various scenarios and seamless integration with different robotic systems.

Key Recommended Products:

As robots move, they may encounter downward steps or ground depressions. Without appropriate sensors todetect and respond to these situations, there is a risk of the robot falling.

The TF series LiDAR, as a distance sensor, features a compact size, high accuracy, and fast measurement frequency,making it suitable as a fall prevention sensor for robots. The LiDAR can detect distance information in real-time and send it to the robot, enabling the robot to promptly react by braking, slowing down, or turning to avoid falling at steps or depressions.

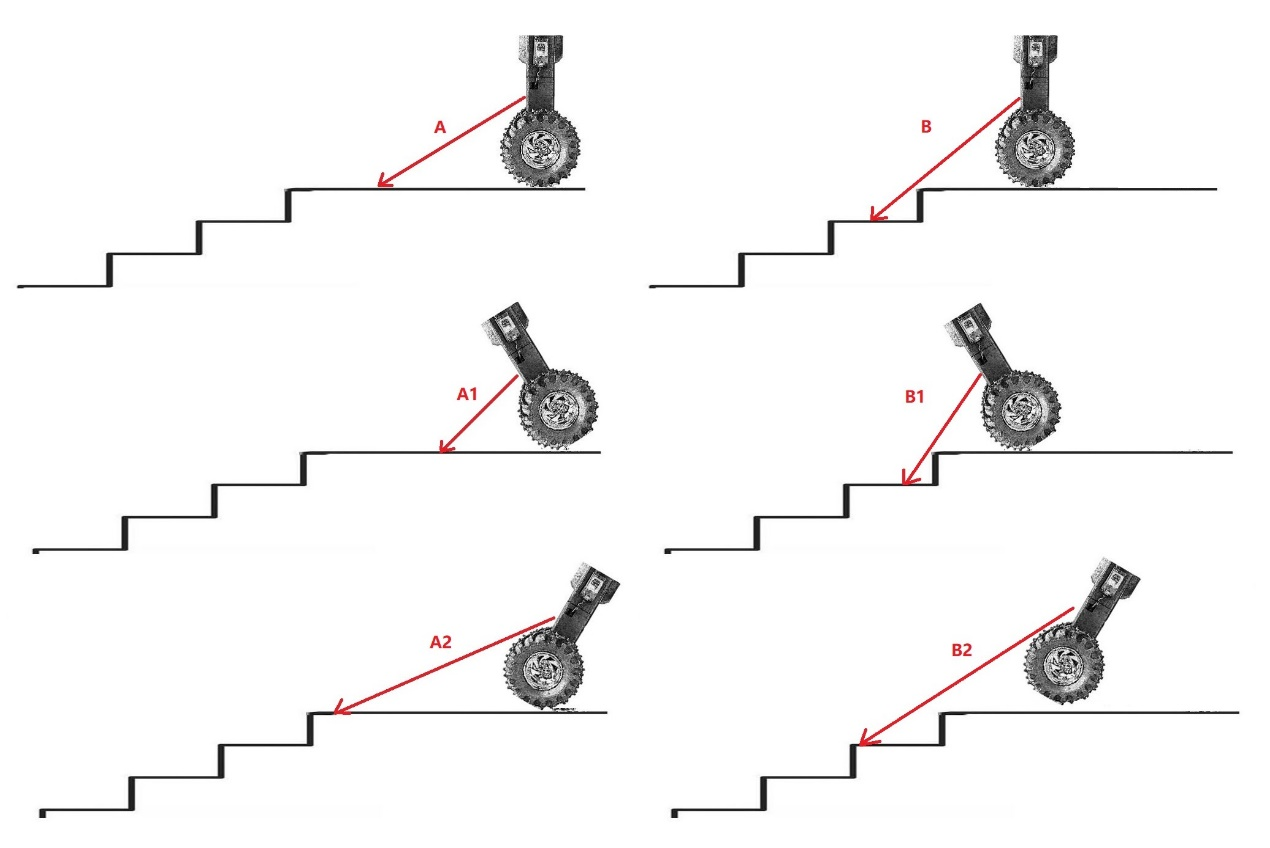

Application Principle

The TF series LiDAR installed on the robot detects distance information in real-time at a certain angle pointing obliquely downward. When the road surface is flat, the measured distance values will stabilize within a certain range. When there are abnormalities on the road surface, the distance values will exceed the reasonable range, resulting in sudden distance changes. This can be judged as the presence of a step or a depression ahead, prompting the robot to slow down or turn to prevent it from falling.

Key Recommended Products:

Robot Obstacle Avoidance

Nowadays, robots are ubiquitous in our daily lives, coming in various types and bringing convenience to our lives. However, if robots cannot quickly and accurately perceive and measure their environment during movement, they are likely to collide with obstacles or people, causing economic losses or personal safety accidents. Benewake’s independently developed single-point solid-state LiDAR, based on the ToF principle, can achieve fast, precise, and stable distance measurement. When integrated into the robot, it can provide real-time distance information, helping the robot quickly and accurately identify surrounding objects, thereby achieving rapid and precise obstacle avoidance.

Application Principle

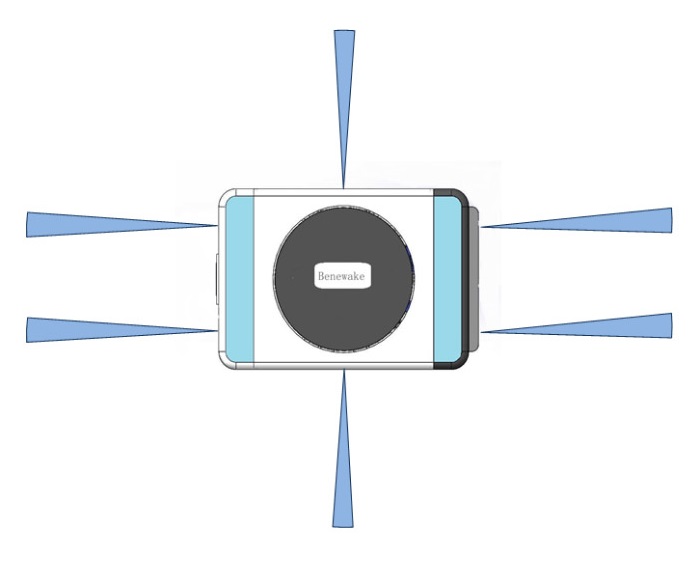

Integrate the TF series LiDAR at the front or around the robot. The installation height can be adjusted according to the robot's shape and scene requirements, typically greater than 10 cm. The LiDAR provides real-time distance information to the robot's MCU. A pre-set warning distance range for obstacles can be configured in the MCU. Within the safe distance range, the robot can move autonomously. When an obstacle enters the warning range, the MCU will control the robot to slow down, turn, or perform other maneuvers to avoid collisions with obstacles.

AMR&RGV&AGV Obstacle Avoidance

With the development of the market logistics industry, human labor can no longer support the vast logistics transportation system, leading to issues such as inaccurate data, inability of management to promptly handle out-of-stock and overstock situations, significantly reducing the operational efficiency of logistics transportation. To improve market share and transportation efficiency while reducing labor and overall transportation costs, Benewake has introduced AMR, AGV, and RGV obstacle avoidance solutions to assist the industry in moving towards more stable, flexible, and rapid automation.

① Outdoor Applications

Outdoor applications refer to AGVs that operate outdoors and feature autonomous navigation. Their primary application scenarios include streets, factories, office buildings, and shopping centers. Functions include cleaning, security, inspection, and delivery. Major categories include outdoor cleaning AGVs, outdoor security patrol AGVs, substation inspection AGVs, and logistics delivery AGVs.

Installing LiDAR on the front of AMRs, AGVs, and RGVs allows them to recognize obstacle positions and distance information, which is fed back to the AMRs, AGVs, and RGVs. After processing, they can issue warnings or avoid obstacles.

② Indoor Applications

Indoor applications mainly involve warehouse AGVs and service AGVs, with a focus on warehouse AGVs.

Warehouse AGV systems consist of a series of picking robots, mobile shelves, replenishment/picking workstations, and other hardware systems, with an AI algorithm-based software system at the core to complete processes such as shelving, picking, replenishment, returns, and inventory. Main application scenarios include e-commerce logistics warehouses, with some manufacturers applying them to production lines, such as in the automotive industry.

As the core module of warehouse AGVs, picking AGVs are involved in all business processes within sorting areas (including shelving, replenishment, picking, inventory, and returns). According to system assignments, they transport target shelves to workstations. After employees complete their tasks under system guidance, the AGVs return the shelves to the sorting area.

Irregular Vehicles - Forklift Fork Obstacle Avoidance

In warehouses where forklifts operate, encountering staff or various obstacles is common. Without effective sensing of the distance between the forks and obstacles, collisions and accidents may occur, leading to equipment damage and personal injury. Currently, most forklifts use photoelectric switches on their forks, which can only provide information on the presence or absence of obstacles but cannot output precise distance information. This limits the forklift's operation to simple braking maneuvers without the ability to control braking speed based on the distance to the obstacle, resulting in low operational efficiency.

Using the TF series single-point LiDAR, forklifts can receive high-speed, accurate distance information. The forklift can then set different deceleration intervals based on this data, improving its operational efficiency.

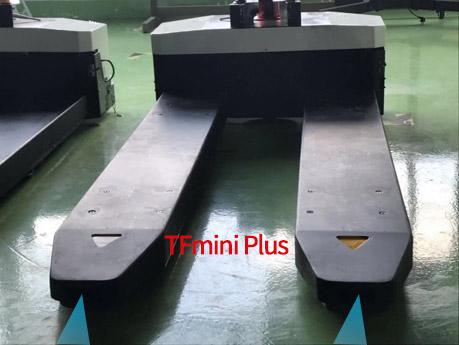

Application Principle

Install the TF series single-point LiDAR inside the fork, facing forward to detect obstacles. The LiDAR will continuously detect obstacles in front of the forks in real-time and provide distance information to the forklift. When an obstacle or person appears within the warning range in front of the forks, the forklift will take deceleration or braking measures based on the distance information to avoid collisions. Customers can set different deceleration ranges for the forklift based on its operating speed. For example, no deceleration is needed within 5m-10m, slow deceleration within 2m-5m, and emergency braking within 2m. This effectively enhances the forklift's operational efficiency.

1. Small size, easy to embed inside robots;

2. High measurement frequency, adaptable to various operating speeds;

3. Low power consumption, saving labor and material costs;

4. High ranging performance, high energy redundancy, adaptable to various installation angles;

5. High distance measurement accuracy, long range, high stability;

6. Low cost, multiple models available;

7. Multiple interface options: UART, IIC, IO;

8. Special obstacle recognition algorithm accurately identifies obstacle information;

9. Provides SDK to improve development efficiency.

Partial Applications

Tunnel inspection robots, outdoor cleaning robots, outdoor patrol robots, substation inspection robots, logistics delivery robots, elevated railway inspection, industrial automation robots, snow sweeping robots.

Key Recommended Products: