VLS Series

Long Distance Series Product Model

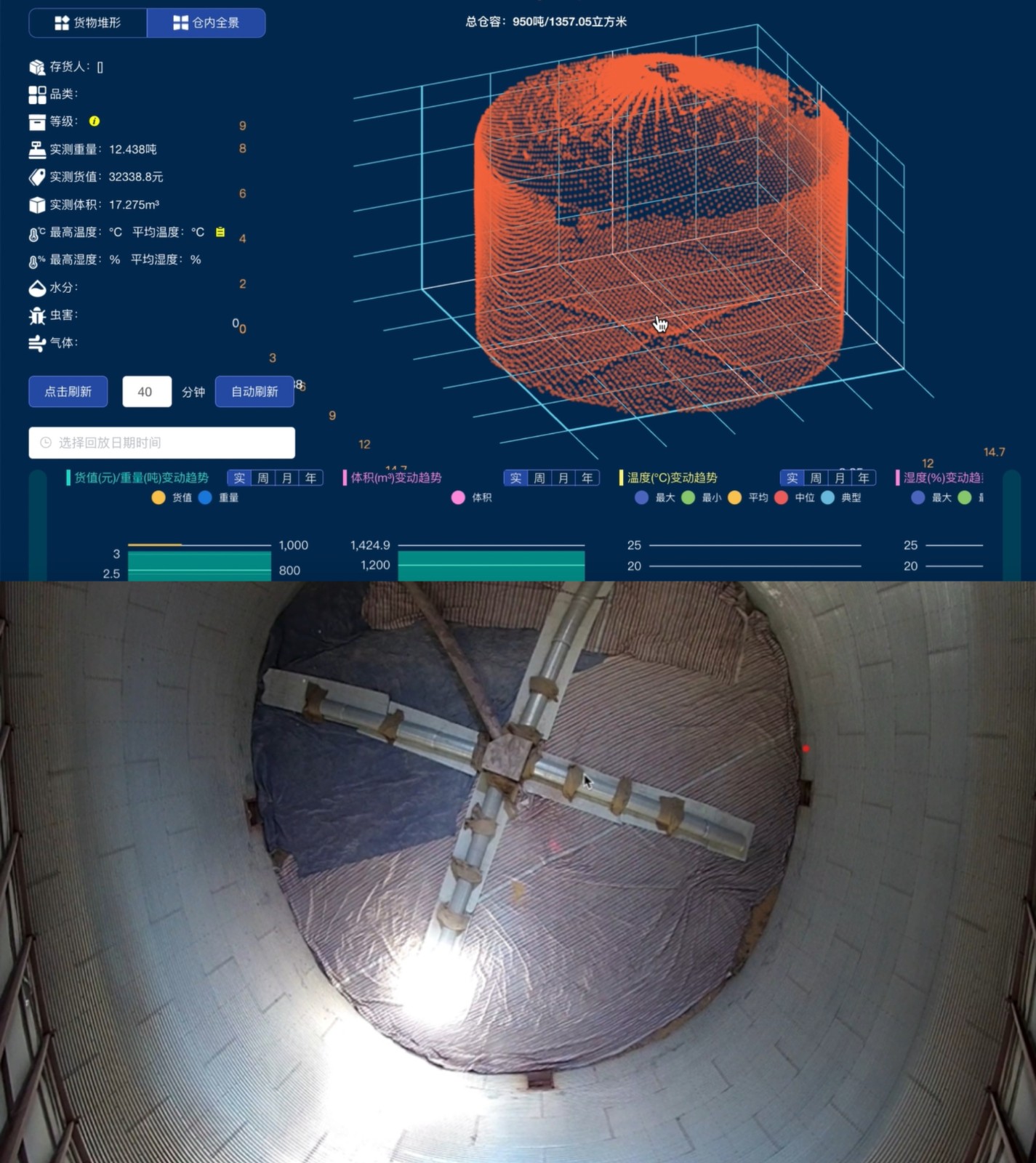

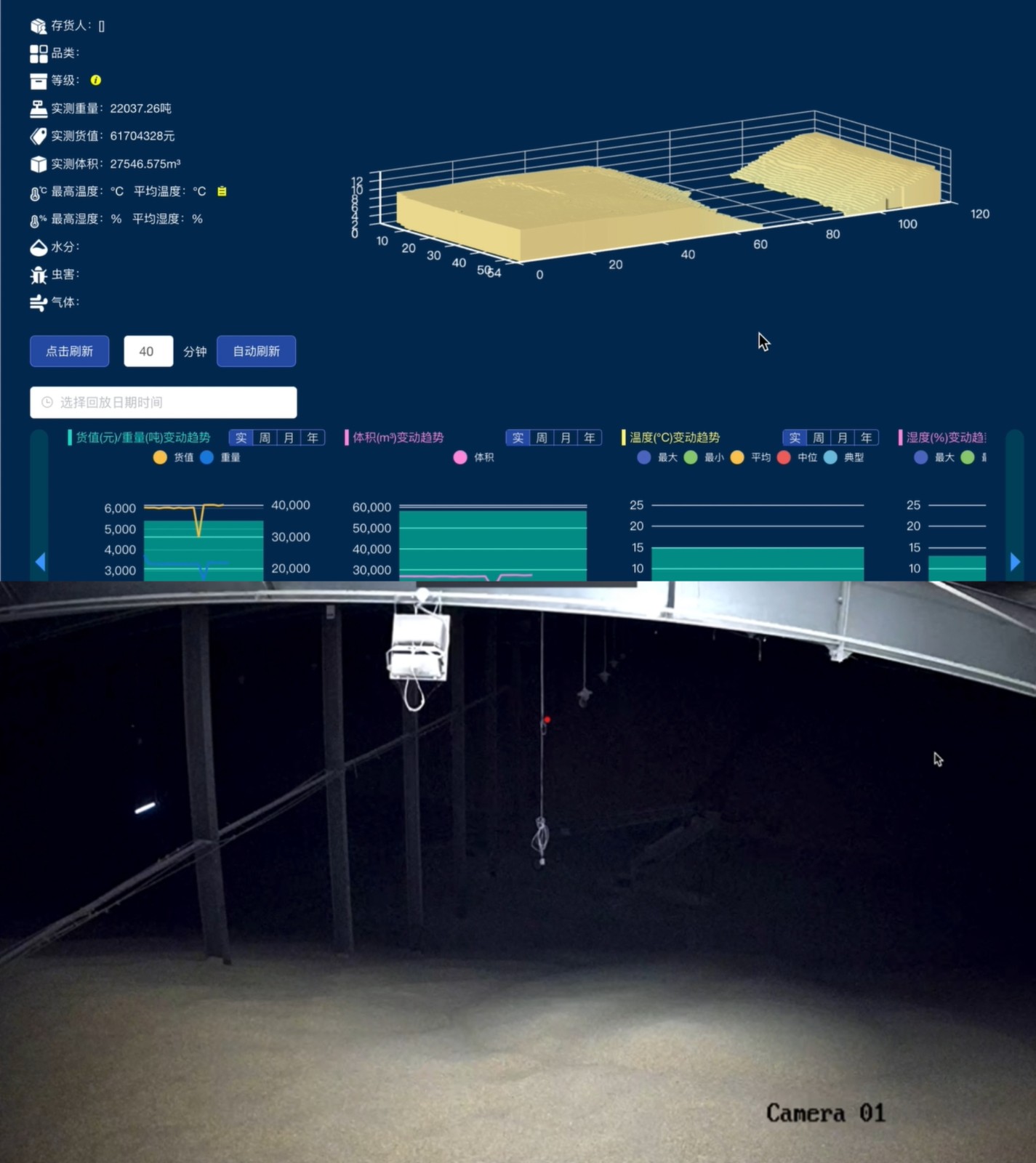

The LiDAR volume detection system is a high-precision detection LiDAR with a 120°*120° wide field of view that generates high-density point clouds. It has built-in algorithms that directly output volume measurements, making it suitable for 3D reconstruction and volume detection systems for targets such as material levels, coal piles, and grain silos. The system integrates different ranges of Benewake TF series LiDARs, with a maximum range of up to 180 meters to meet the distance measurement needs of different customers.

Material level volume detection / Coal pile volume detection / Grain silo volume detection / 3D reconstruction ......

The LiDAR volume measurement system is installed at the top or side of a storage tank to monitor the grain surface distance in real-time. The built-in main control board calculates the remaining material volume in real-time, facilitating timely feed replenishment.

1. Self-Cleaning (Dust Removal) Function

The system includes a wiper configuration to prevent excessive dust from affecting the sensor's distance measurement accuracy.

2. Multi-Line Scanning Function (Adjustable Angle | Speed | Time)

The system includes a servo that sweeps at fixed intervals, performing one back-and-forth sweep between 0° and 120°.

The current highest resolution of the system is one point per degree (14400 points for a 120° scan). The current scan step for the secondary joint is 1° with a 50ms delay (adjustable threshold 20-100ms), and the primary joint step is 1° with a 500ms delay (adjustable threshold about 80ms-1000ms). Scanning 120°120° takes about 60 seconds, and scanning 60°60° takes about 30 seconds. The smaller the angle, the faster the scan time.

3. Wireless Transmission Function

The system is equipped with a wireless transmission module, allowing the wireless monitoring center to receive real-time information on the remaining material volume at the monitored point. The data transmission is stable, and wireless transmission can use LORA to transmit signals to the DTU for transparent transmission.

4. Parameter Configuration

Users can configure the scanning angle, cone angle, self-cleaning time, device self-check, and basic parameters of the silo for secondary development.

5. External Trigger Measurement

Upon receiving an external trigger signal, the system completes a scan and outputs the volume value.

6. Step Grid Scanning Method

By performing arc scans with two rotating servos, the system can generate a grid-like planar map, forming a fitable 3D point cloud.

1. Eye Safety Certification: CCIC testing exemption level (EN62471)

2. Laser Safety Level: Class 1

3. Vibration and Shock Report: Available

|  |  |

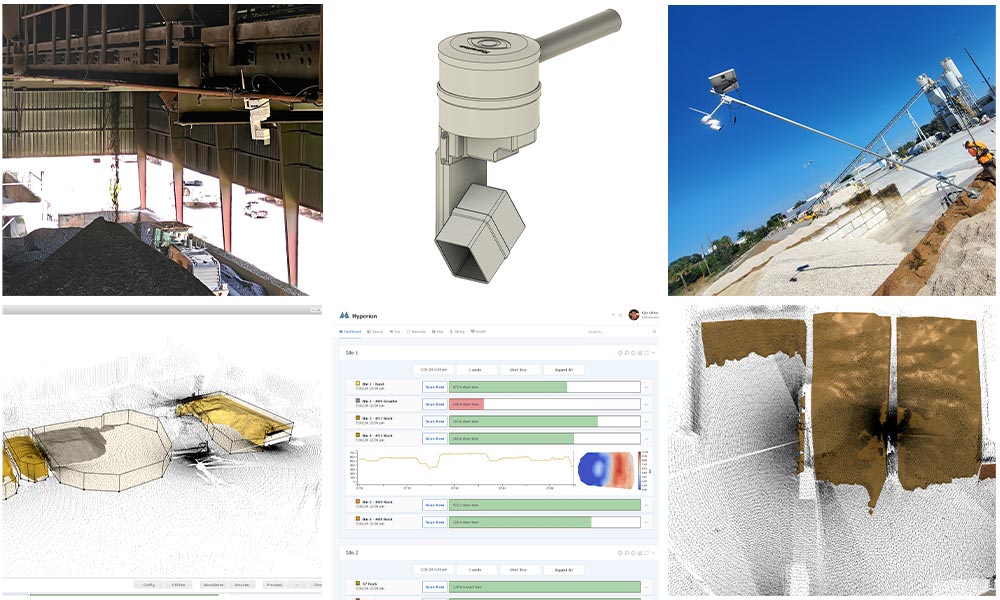

Hyperion Real-Time Stockpile Measurement System

Powered by Benewake LiDAR | Developed by Altamus Inc.

The Hyperion system revolutionizes material inventory management by offering real-time, precise volume measurements of stockpiles using Benewake's advanced LiDAR sensors. It eliminates manual measurements and provides continuous, automated updates, even in challenging industrial environments.

Key Features & Benefits

Real-time Monitoring – Continuous, automated inventory tracking throughout production cycles.

High Accuracy & Reliability – 1% volumetric measurement accuracy with<1% deviation in full-bin scenarios.

Weather-Resistant Design – IP54-rated scanners operate reliably in harsh conditions.

Flexible Deployment – Compact, lightweight, and mountable on poles, I-beams, or structural frameworks.

Seamless System Expansion – Multiple scanners networked with advanced synchronization and data stitching.

Automated Reporting – Integration with inventory systems via intuitive software dashboard.

Technical Highlights

Specification | Details |

Power | 12VDC | 2A peak | 6W during scan |

Mounting | 3/4" NPT standard |

Communication | 2.4 GHz WiFi |

Protection Rating | IP54 |

Angular Accuracy | 0.25° |

Rangefinder Accuracy | ±1% |

Per Scanner Range | <150 ft |

System Range | Unlimited (via networked scanners) |

Scan Speed | Full 360° in 3 minutes |

Applications

Cement Batch Plants – Optimize raw material usage and production scheduling.

Industrial Facilities – Monitor inventory of aggregates, sand, gravel, and other bulk materials.

Construction Sites – Track material deliveries and on-site consumption in real time.

Deployment Examples

Outdoor Stockyards – Mounted on standard EMT poles for elevated coverage.

Covered Facilities – Secured to beams or walls in sheds and indoor storage areas.

Remote Locations – Compatible with solar power for off-grid operation.

Why Choose Hyperion?

Hyperion combines Benewake’s trusted LiDAR modules with intelligent software and scalable deployment. Facilities benefit from:

Reduced manual labor

Increased measurement accuracy

Real-time material visibility

Streamlined operations across multi-site networks