Short Distance Series Product Model

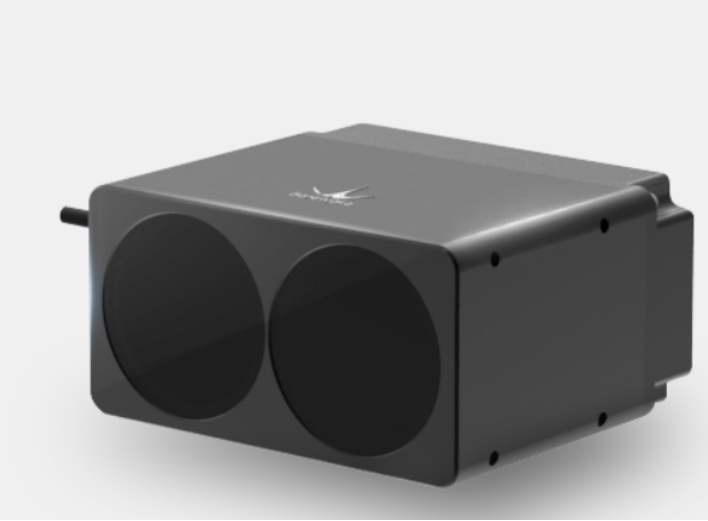

Long Distance Series Product Model

Kilometer-level

Long Distance Series Product Model

2024-10-11

Our sensors are designed for accuracy and reliability, but like any advanced technology, they can encounter issues from time to time. In this article, I will discuss some common problems with long range laser sensors and how to troubleshoot them effectively.

Understanding Measurement Errors

One of the most frequent issues users experience with long range laser sensors is measurement errors. At Benewake, we understand that even minor discrepancies can lead to significant consequences, especially in critical applications like surveying and autonomous navigation. If you notice inconsistent readings or errors in distances measured, there are a few steps to consider.

First, ensure that the sensor is properly calibrated according to the manufacturer’s specifications. Calibration helps maintain accuracy, and an out-of-calibration sensor can lead to erroneous data. Additionally, check for any obstructions in the sensor’s line of sight. Objects blocking the laser path, such as dust or debris, can interfere with measurements. Regular cleaning and maintenance can help mitigate these issues, ensuring that our long range laser sensors operate optimally.

Addressing Environmental Interference

Another common challenge faced by users of long range laser sensors is environmental interference. Factors such as rain, fog, or strong sunlight can affect the performance of the sensor. At Benewake, we design our long range laser sensors to perform well in various conditions, but extreme weather can still impact measurement accuracy.

To address this, always ensure that the sensor is rated for the environmental conditions it will be operating in. If you frequently work in adverse weather, consider using additional shielding or protective covers to minimize exposure to harsh elements. Furthermore, evaluate the angle of the sensor; certain angles might reduce the impact of reflections or scattering caused by environmental factors, leading to more reliable readings.

Power Supply and Connectivity Issues

Issues related to power supply and connectivity are also common when using long range laser sensors. If your sensor is unresponsive or shows erratic behavior, check the power source first. At Benewake, we emphasize the importance of using a stable power supply to ensure consistent operation. Make sure that all connections are secure, and consider using surge protection to prevent damage from electrical fluctuations.

If the problem persists, examine the data transmission methods between the sensor and your processing unit. Faulty cables or loose connections can disrupt the flow of information, leading to incomplete data. By thoroughly investigating the power and connection systems, you can resolve many common issues quickly and effectively.

Conclusion

In conclusion, while long range laser sensors from Benewake are built for durability and precision, troubleshooting common issues is essential for maintaining optimal performance. By understanding measurement errors, addressing environmental interference, and ensuring secure power supply and connections, you can enhance the efficiency of your long range laser sensor. We are committed to supporting our customers by providing guidance and solutions for any challenges they may encounter.