Short Distance Series Product Model

Long Distance Series Product Model

Kilometer-level

Long Distance Series Product Model

2024-06-19

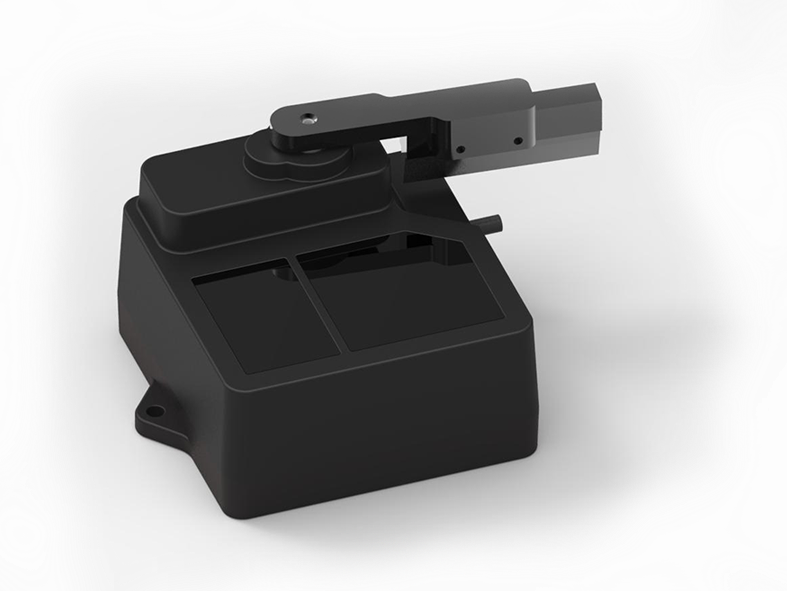

In an era where precision and efficiency define success in industrial operations, Benewake is proud to introduce the TF02-Pro-W, a high precision laser distance sensor specifically designed for bulk material volume monitoring. This single-point LiDAR not only shares the advanced features of its predecessor, the TF02-Pro, but also incorporates a unique self-cleaning mechanism, making it perfectly suited for environments where dust and debris are prevalent. The TF02-Pro-W is an exemplary model of how industrial LiDAR sensors are evolving to meet the complex demands of modern industries.

Innovative Self-Cleaning for Continuous Accuracy

The standout feature of the TF02-Pro-W is its built-in self-cleaning module, which includes a small squeegee integrated directly into the sensor. This design is engineered to automatically remove dust from the LiDAR's cover glass, thereby maintaining high measurement accuracy even in extremely dusty settings like those found in mining, agriculture, or material processing facilities. The self-cleaning function is powered by the LiDAR itself and offers customizable settings to adapt to various operational environments, significantly reducing maintenance time and cost.

Enhanced Connectivity and Power Flexibility

Understanding the need for versatile and robust communication in industrial settings, the TF02-Pro-W supports multiple connectivity options, including UART, I²C, RS485 ports, and the Modbus protocol. Additionally, it accommodates various wireless data transmission methods such as LoRaWAN, 4G, and Wi-Fi, ensuring seamless integration into existing systems. The sensor's battery-powered design enhances its portability and ease of installation, providing greater flexibility in deployment across different sites and platforms without the need for complex wiring or electrical setups.

Precision Measurement with Advanced Sensing Technology

The TF02-Pro-W utilizes Time of Flight (ToF) technology for non-contact measurement, ensuring that the integrity of both the sensor and the measured materials remains uncompromised. This feature is crucial for industries where material contamination can lead to significant operational setbacks or safety issues. Additionally, the sensor's narrow Field of View (FoV) and built-in dust-filtering algorithm work together to provide highly accurate measurements essential for efficient volume monitoring and management. This precision is particularly valuable in applications where exact material quantification can lead to better resource management and cost savings.

Conclusion

Benewake's TF02-Pro-W industrial LiDAR sensor marks a significant advancement in LiDAR technology tailored for industrial applications. By integrating self-cleaning capabilities, flexible connectivity options, and precision measurement technology, the TF02-Pro-W addresses some of the most challenging aspects of industrial operations. As industries continue to evolve and demand more from technology, Benewake remains committed to delivering innovative solutions that not only meet but exceed these expectations. The TF02-Pro-W is more than just a sensor—it is a pivotal tool in optimizing the efficiency and accuracy of industrial processes, ensuring that our clients are equipped to succeed in a competitive and ever-changing market.