VLS Series

Long Distance Series Product Model

With the rapid development of the shipping industry, the safety and efficiency of vessel operations have become focal points of concern within the industry. The introduction of advanced technologies such as automated monitoring is particularly crucial. These technologies not only effectively prevent collision accidents during vessel operations but also enhance overall operational efficiency. They elevate vessel management to a level of orderliness, rationality, and high efficiency, further driving the intelligent development of the shipping industry.

Based on the intelligent waterway solution utilizing Benewake's high-performance 3D LiDAR, remote monitoring of water areas can be conducted around the clock even in adverse weather conditions. This system gathers 3D information and spatial positions of vessels navigating within the monitoring area, swiftly and accurately determining vessel size and location, as well as monitoring vessel traffic and navigation trajectories. This not only effectively reduces collision accidents but also provides the system with high-precision perceptual capabilities to achieve full-process automation.

|

|

| ||

Wide FoV 120°×25.6°,complete coverage with minimal installation | Long Range Capable of detecting vessels up to 300 meters away, providing early warning to reduce collision risks | High Resolution 256 lines , accurate determination of ship's hull profile | ||

|

|

| ||

Ultra-High Precision ±3cm accuracy, effectively detects distance between vessel and bridge | High Protection IP67&IP6K9K,MTBF≥50000h | All-Weather Operational Capability 24/7 operational capability, unfazed by day or night and harsh environments |

With the rapid development of inland waterway transportation, maritime agencies and port authorities are gradually adopting shipping information management systems. Port authorities urgently require automated, accurate, and effective monitoring of vessel traffic and data collection.

By installing Benewake's high-performance 3D LiDAR on bridges, it becomes possible to conduct 24/7 detection of waterways and observe and statistically analyze vessel traffic. The system automatically records information such as the number of vessels passing through, their headings, speeds, lengths, widths, trajectories, cargo status, and over-height conditions. This objectively reflects the waterway traffic conditions, providing stable and reliable data support for the informationization of waterways.

Benewake LiDAR boasts automotive-grade reliability, with IP67 protection and an MTBF exceeding 50,000 hours. It operates stably for long periods in high-humidity environments, requiring minimal on-site maintenance and reducing subsequent maintenance costs.

By providing coordinated ship-shore communication and advance warning, personnel and vessels are safeguarded, effectively preventing bridge collisions and minimizing safety hazards. This injects new vitality into the informationization of waterways.

Benewake's high-performance 3D LiDAR, installed on bridges or shores, has a detection range of over 300 meters. For vessels with large dimensions, tonnages, and longer braking distances, as well as various shapes, early detection and warning of targets and timely issuance of collision avoidance instructions provide longer stopping and course correction times for the operators. During the flood season water level changes, Benewake LiDAR's image-level resolution accurately reflects vessel contours, identifies the highest points of different vessel types, determines safe clearance heights, anticipates collision risks, and greatly ensures the safety of personnel, vessels, and bridges.

By installing Benewake's high-performance 3D LiDAR on bridges or shores, equipped with 256 lines of high resolution and automotive-grade reliability, it enables all-weather, high-precision 3D profile detection of passing vessels. For vessels exceeding height and width limits, timely alarms are issued, prohibiting passage under bridges and avoiding collision risks. This significantly reduces the probability of vessel-bridge collision accidents while also reducing personnel management costs, labor costs and safety risk management costs.

Guangxi Nanning Smart Waterway Project - Achieving Vessel Traffic

Statistics and Bridge Collision Warning Functionality

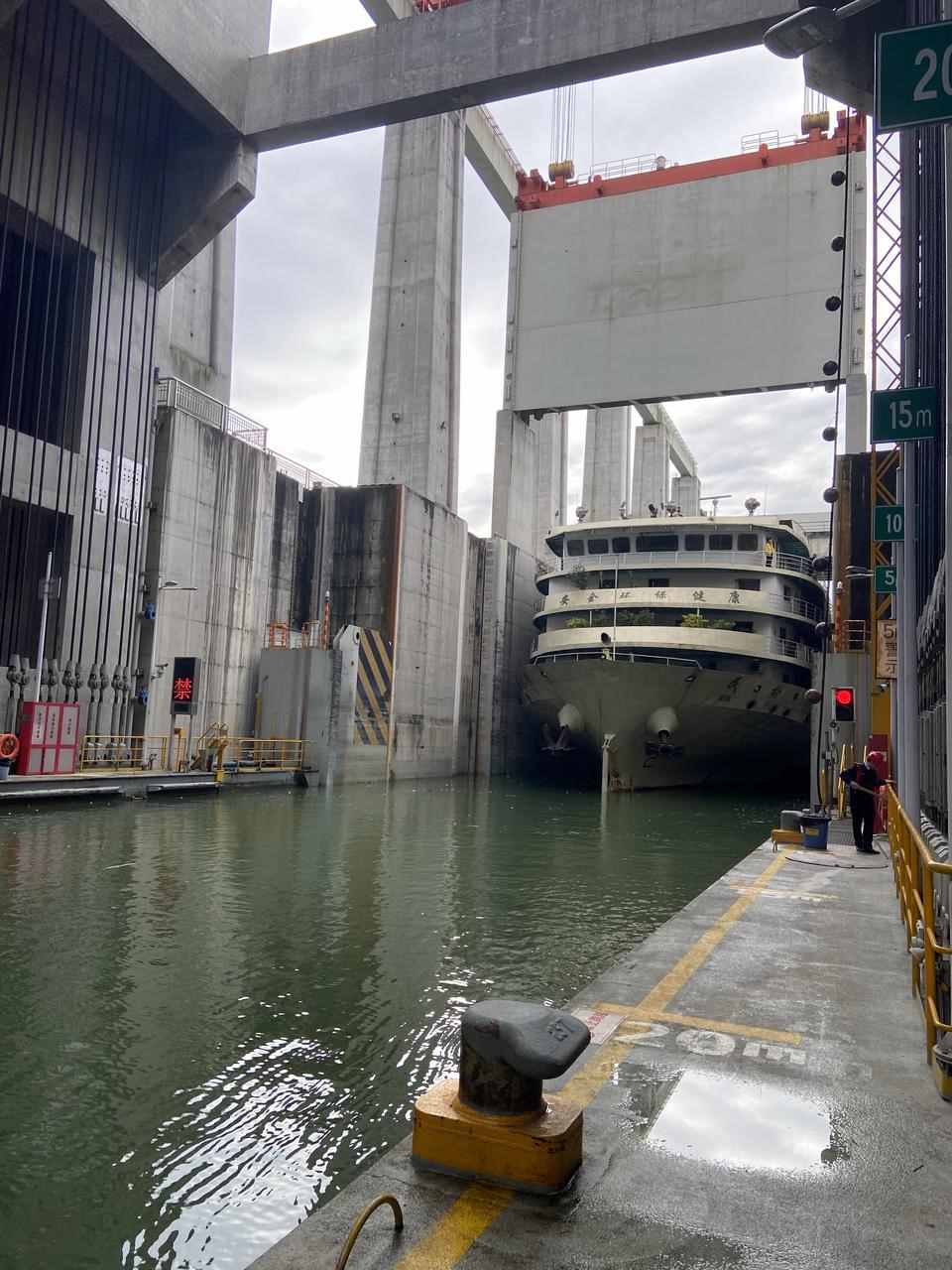

The Smart Lock System enables remote centralized control of various locks, saving on manual costs while providing real-time insights into the number and timing of vessels passing through locks. This allows for orderly regulation, reducing waiting times and facilitating the intelligent management of the entire transportation process, automation of lock operations and integration of transportation control datas. It promotes inland waterways to accelerate their paces of development.

Benewake's high-performance 3D LiDAR meets the real-time monitoring requirements of the Smart Lock System for vessels. It provides the system with high-precision 3D vessel profiles and spatial positioning data, guiding navigation information for safe and swift vessel passage through locks. This support safe supervision of vessel passage through locks, effectively reducing the probability of vessel collisions, and promoting the efficient application of the system.

Accurate Identification of Vessel Speed

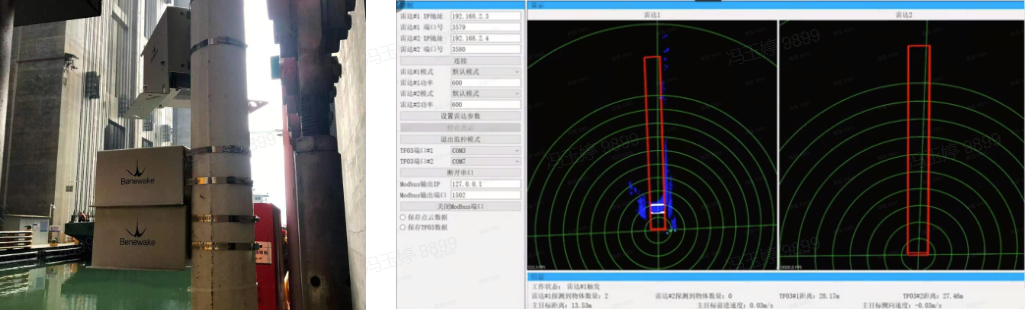

Due to limited space in the lock and the large size of vessels, it is necessary to dock multiple vessels simultaneously. However, vessel operations are not flexible, and if vessels exceed speed limits or fail to maintain proper distance, collisions are likely. The Benewake ultra-high precision LiDAR can calculate real-time vessel speed using point clouds, with an accuracy of 0.1 m/s. This system can promptly issue alerts for speeding vessels, reducing collision risks and ensuring safe passage through the lock.

Precise Identification of Vessel Dimensions

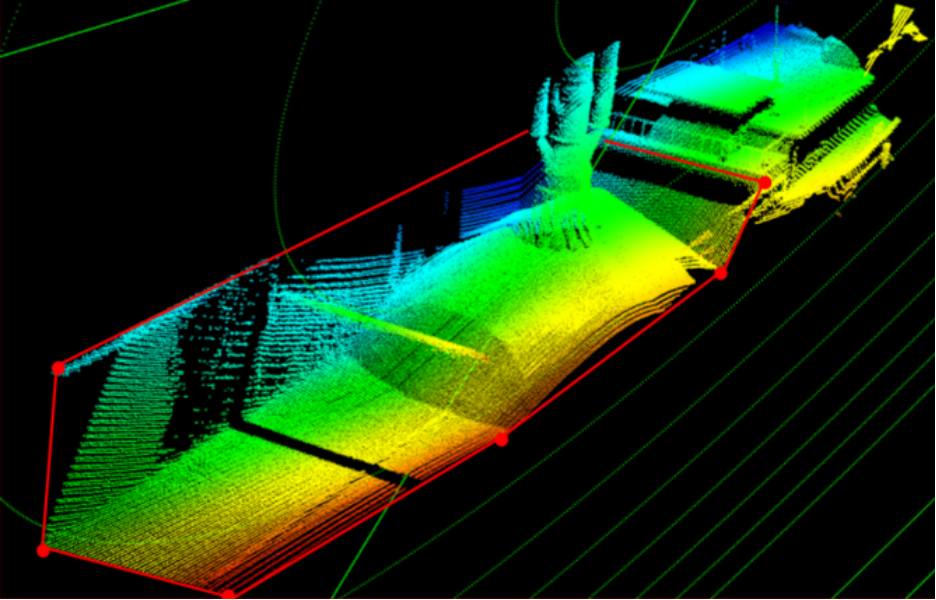

To enhance the capacity and efficiency of locks, it is necessary to accommodate as many vessels as possible within the limited space. The Benewake ultra-high precision LiDAR can accurately identify the three-dimensional dimensions of vessels with decimeter-level precision, providing accurate data support for the intelligent dispatch system of the lock. This improves transportation capacity and efficiency, allowing for the maximum accommodation of vessels.

High Distance Measurement Accuracy

In the confined space of a lock, the distance between vessels is minimal, and operations are not flexible, increasing the risk of collisions if not carefully managed. The Benewake ultra-high precision LiDAR can accurately measure distances. When the distance exceeds the preset warning threshold, it can promptly issue alerts and provide correct guidance, reducing collision risks and ensuring the safety of vessels and personnel.

High Protection Level and Reliability

The maritime environment is characterized by high humidity, and the unique operating conditions of bridges make frequent maintenance of sensors inconvenient. Therefore, sensors require high protection levels and reliability. The Benewake LiDAR meets automotive-grade standards, has an IP67 protection rating, and an MTBF (Mean Time Between Failures) of over 50,000 hours. It can operate stably for long periods in high humidity environments with high reliability and does not require frequent on-site maintenance, significantly reducing post-maintenance costs.

Reduced Installation and Deployment Costs

The monitoring range of the lock is fixed, but the significant height differences during the water filling and draining processes require downward detection from the top of the dam. Therefore, LiDAR needs a wide field of view to cover the entire area while minimizing the number of units. The Benewake LiDAR has a wide field of view of 120°*25.6°, capable of covering the entire area during significant height changes in the water filling and draining processes, thereby minimizing the number of units needed and reducing costs.

Three Gorges Ship Lift Project - Ship Distance and Speed Recognition

Smart Lock Application Real-Time Ship Speed and Distance Detection Point Cloud Effect

Jiangsu Smart Lock Project - Ship Size Detection and Yaw Detection

Dynamic Point Cloud Effect Video for Ship Yaw Monitoring

As international trade continues to grow and port logistics expand, improving the efficiency and safety of container loading and unloading is essential. To achieve this, ports and enterprises must invest in automation and intelligent technology, adopt advanced equipment and systems, and improve operational precision and efficiency.

The intelligent 3D simulation system for ship-loading uses high-performance LiDAR from Beneweke, which can monitor distance, collisions, and material status in real-time and from all angles during the loading process. This improves the efficiency and safety of ship-loading operations. Moreover, the laser radar is the most accurate positioning sensor on the market and can provide centimeter-level accuracy for automatic container grabbing by port gantry cranes and other equipment. These technological applications help to reduce operational risks and provide more efficient and safer ship-loading services for enterprises.

|

|

| ||

Wide FoV 120°×25.6°, it can monitor large-sized ship holds, providing comprehensive detection coverage | Dual Echo The detection shall be reliable even in dust | Gaze Function Fully adjustable across the entire field of view, doubling the resolution in focused areas of interest | ||

|

|

| ||

High Protection Level Featuring IP67 protection, it can operate stably in high humidity and heavy dust environments | Fine Target Perception Clear target contours, capable of outputting 3D positional differences | All-Weather Monitoring Operating 24/7, it reduces personnel costs |

The Smart Ship Loading System employs multiple high-performance 3D LiDARs manufactured by Benewake to provide collision avoidance warnings during unloading and volume measurement functions, thus achieve intelligent ship loading. The system covers a complete loading process, including automatic ship detection, ship hold positioning, and gantry tube positioning.

Accurate Pile Identification to Prevent Ship Tipping

Bulk cargo loading requires real-time monitoring of unloading positions and pile volumes to prevent ship tipping. Benewake LiDARs with high resolution and frame rates can monitor unloading positions and pile volumes in real-time. They issue alerts when improper unloading sequences or excessive piling on one side of the ship hold is detected. This helps operators adjust unloading operations promptly to ensure safe and efficient unloading.

Accurate Feature Recognition to Avoid Collision Risks

When loading bulk materials, it's crucial to have precise control over the position and extension of the gantry tube to prevent collisions between the tube and the ship hold, which can result in the ship tipping over. Benewake LiDARs can precisely identify the features of both the gantry tube and the ship hold, determine their position, and record the gantry tube's trajectory. Alerts will be triggered when collision risks are detected, preventing collisions and reducing onboard guidance manpower, thereby improving operational efficiency.

Accurate Unloading Identification to Enhance Efficiency and Reduce Dust Pollution

During unloading, excessive lifting speed of the gantry tube can cause dust pollution, while slow lifting speed can affect efficiency. Benewake LiDARs with high frame rates and strong real-time monitoring capabilities can judge the lifting speed of the gantry tube based on the status of the pile and dust. Alerts are issued promptly when excessive or insufficient lifting speed is detected, thus guiding operators to perform precise operations and improve unloading efficiency.

The Automatic Ship Loading Project at the Chizhou Port

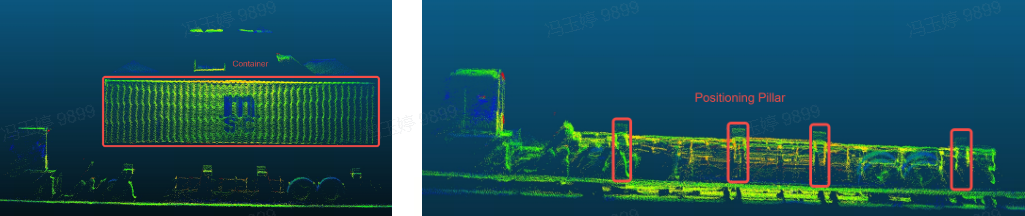

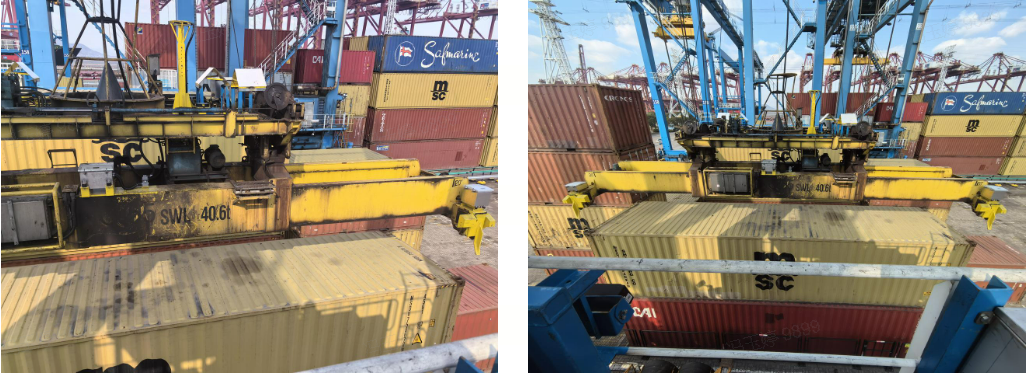

LiDAR mounted on gantry crane hoists can be used for both loaded and unloaded container trucks. In typical scenarios, LiDAR generates point clouds and gives relative 3D positions of containers, container trucks, operation markers, and the environment, providing dynamic positional references for automated operations to ensure production safety.

LiDAR enables features like centimeter-level target positioning, perception of relative environmental positions of targets, target center trajectories, and perception of target swing angles.

Point Cloud - Container Lifting Process Point Cloud - Empty Container Truck & Positioning Pillar

Container Truck Positioning Project

Container Crane Components Front View of Container Crane