VLS Series

Long Distance Series Product Model

2024-08-30

As a leading provider of innovative LiDAR technology, Benewake is dedicated to empowering our customers with cutting-edge solutions that redefine the possibilities in industrial automation. In this comprehensive guide, we will share our insights on how you can seamlessly integrate industrial LiDAR sensor into your automated systems to enhance efficiency, safety, and productivity.

Understanding the Benefits of Industrial LiDAR Sensors

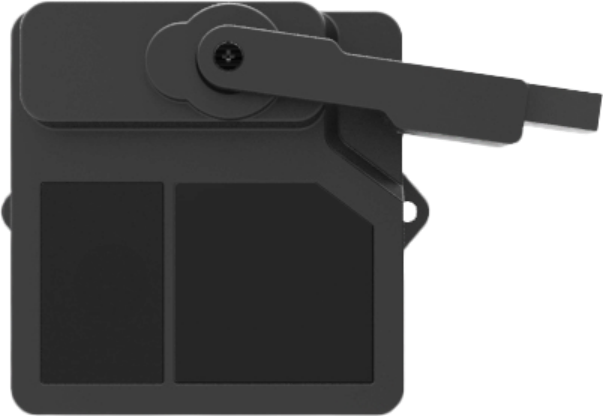

Industrial LiDAR sensors, such as Benewake's TF02-Pro-W, offer a range of advantages that can revolutionize your industrial automation processes. These sensors provide precise, real-time 3D data, enabling accurate object detection, measurement, and mapping. This capability is particularly valuable in applications where safety and precision are paramount, such as robotic navigation, collision avoidance, and dimensional quality control.

Selecting the Right Industrial LiDAR Sensor

When it comes to integrating industrial LiDAR sensors, it's crucial to choose a solution that aligns with your specific requirements. Benewake's TF02-Pro-W, for instance, is designed to excel in harsh industrial environments, featuring an IP67 rating, extended operating temperature range, and robust construction.

Seamless Integration through Versatile Communication

Seamless integration is the key to successfully leveraging industrial LiDAR sensors in your automation solutions. Benewake's TF02-Pro-W offers a range of communication options, including UART, I²C, RS485, and Modbus protocol, ensuring compatibility with a wide variety of industrial control systems and devices.

Wireless Connectivity for Enhanced Flexibility

In addition to wired connectivity, Benewake also offers industrial LiDAR sensors with wireless communication capabilities. The TF02-Pro-W, for example, supports LoRaWAN, 4G, and Wi-Fi, providing greater flexibility in deployment and data transmission, especially in applications where wired connections are impractical or challenging to implement.

Reliable Performance in Demanding Environments

Industrial automation often requires equipment to withstand harsh conditions, such as extreme temperatures, vibrations, and dust. Benewake's TF02-Pro-W industrial LiDAR sensor is designed to thrive in these demanding environments, with an IP67 rating and extended operating temperature range from -40°C to 70°C.

Seamless Integration with Industrial Control Systems

To ensure a smooth integration process, Benewake's industrial LiDAR sensors are designed to work seamlessly with a variety of industrial control systems, including programmable logic controllers (PLCs), industrial PCs, and supervisory control and data acquisition (SCADA) systems. This compatibility simplifies the integration process and enables you to leverage the sensor's capabilities within your existing automation infrastructure.

Customization and Tailored Solutions

At Benewake, we understand that every industrial automation project has unique requirements. That's why we offer customization and tailored solutions to meet the specific needs of our customers. Whether it's modifying the sensor's performance parameters, integrating custom communication protocols, or developing bespoke software interfaces, our team of experts is dedicated to providing a solution that fits your exact requirements.

Conclusion

Integrating industrial LiDAR sensors into your automation systems can unlock a world of possibilities, from enhanced safety and precision to improved productivity and efficiency. By leveraging the capabilities of Benewake's TF02-Pro-W and its versatile communication options, wireless connectivity, and robust performance, you can elevate your industrial automation to new heights. Take the first step towards transforming your operations and contact Benewake to explore how industrial LiDAR sensors can revolutionize your business.